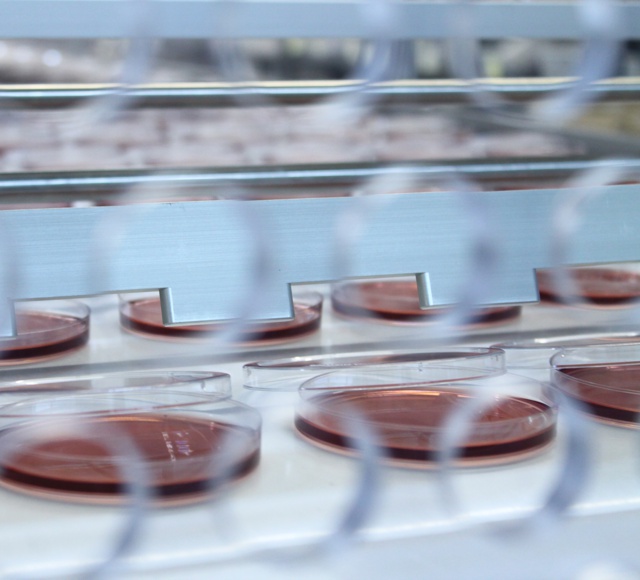

High Speed Petri Dish Filling Machines

MultiDISH™ Production Systems

ONLINE Engineering MultiDISH™ petri dish filling systems accommodate a wide variety of dish types and sizes. Changeover from one dish type to another is accomplished quickly and easily with interchangeable heads, tool-free change parts, and touch panel settings. MultiDISH™ systems fill and process multiple lanes of petri dishes simultaneously with production rates up to 12,000 units per hour.

LEARN MORE

MultiDISH™ MODELS

Throughput estimates are dependent on a variety of manageable production parameters including pour volume, pump speed, and dry time. Each of these parameters can be easily adjusted from the touch screen by an authorized user and can be saved as part of a reusable recipe.

The rates below are based on full length machines and standard handling (full cover removal for contact plates and all dishes on Model 963, partial cover removal for all other plates). Dry time settings for 90mm, 55mm, and 120mm plates is 3 minutes, and for contact and 140mm is 4 minutes. For a side by side comparison, please see the spec sheet linked above.

MODEL 963

3 Lanes of 90mm plates @2400

units/hour

3 Lanes of contact plates @2400 units/hour

3

Lanes of 55mm plates @3000 units/hour

2 Lanes of 140mm plates

@900 units/hour

2 Lanes of 120mm square plates @1000

units/hour

MODEL 965

5 Lanes of 90mm plates @6000

units/hour

5 Lanes of contact plates @4000 units/hour

5

Lanes of 55mm plates @6000 units/hour

3 Lanes of 140mm plates

@1700 units/hour

3 Lanes of 120mm square plates @2200

units/hour

MODEL 968

8 Lanes of 90mm plates @9600

units/hour

6 Lanes of contact plates @6000 units/hour

8

Lanes of 55mm plates @9600 units/hour

5 Lanes of 140mm plates

@2900 units/hour

5 Lanes of 120mm square plates @3600

units/hour

MODEL 964

4 Lanes of 90mm plates @4800

units/hour

4 Lanes of contact plates @3200 units/hour

4

Lanes of 55mm plates @4800 units/hour

2 Lanes of 140mm plates

@1100 units/hour

3 Lanes of 120mm square plates @1400

units/hour

MODEL 966

6 Lanes of 90mm plates @7200

units/hour

6 Lanes of contact plates @5000 units/hour

6

Lanes of 55mm plates @7200 units/hour

4 Lanes of 140mm plates

@2200 units/hour

4 lanes of 120mm square plates @2800

units/hour

MODEL 916

10 Lanes of 90mm plates @12000

units/hour

8 Lanes of contact plates @8000 units/hour

10

Lanes of 55mm plates @12000 units/hour

6 Lanes of 140mm

plates @3500 units/hour

7 Lanes of 120mm square plates @6000

units/hour

FEATURES

-

System Certifications All ONLINE Petri Dish Filling Systems are CE marked. Exterior electrical connections are IP 66 rated.

-

Printer Integration Each system includes an integrated bottom print station designed to accommodate most inkjet print systems (not included).

-

Auto Purge Each system includes an Auto Purge function which will dispense a dose of media at a preset interval, clearing the nozzle tip and preventing gelling while the machine is stopped. Dose volume and purge interval are adjustable in the touch screen (HMI).

-

Flexible Layout Design All system layouts are flexible, offering right/left placement of operator panel, electrical enclosures, and output direction. System length can also be adjusted to accommodate facility requirements.

-

Meniscus Generation Each system includes an adjustable meniscus generation station to create a smooth meniscus, helping media remain in plates when cured or inverted.

-

All ONLINE Engineering Petri Dish Filling systems are made in the USA and are shipped with a one-year warranty. Phone and email support is available for the life of the machine.

OPTIONS

Many options may also be available for retrofit upgrades to existing equipment.

Bulk Loading

Bulk loading reduces the frequency with which an operator must reload the magazine, allowing for additional time spent away from the infeed end of the machine.

Orientation System

The orientation system ensures proper presentation of multicavity dishes for dispense without cross contamination.

Inline Nozzle Heating System

Nozzles heaters utilize heated plates surrounding the nozzles to maintain temperatures between 50-60°C (depending on ambient conditions) in order to minimize media gelling during system stops. This cost-saving option can be added to any new system order and can be retrofitted to many existing ONLINE Engineering petri dish filling systems.

Individual Pump Control

On a standard system, the pumps are synchronously controlled by a single or dual motor system. With individual pump control each pump is controlled by a dedicated motor. This allows for fine tuning of volume on each pump without the need for mechanical adjustment.

Reduced Lane Function

With reduced lane function, production can be run on half of the lanes of the system. This is often preferred when running specialty or low volume production runs.

Inline Rotary Edge and Custom Print Options

An inline rotary edge print station allows for printing and/or barcoding on the side of the dishes. This modular option can be added to a new system order or retrofitted to many existing petri dish filling systems. Many other custom print station options are also available upon request including fixed side printing, lid printing, and dual or multi printer configurations.

Rejection System

The rejection system includes tracking and ejection of dishes. Rows of dishes can be tagged for rejection automatically by the system for a variety of reasons, i.e. failed dispense, hood opening, or selection by the operator. Dishes tagged for rejection are ejected at the end of the cooling tunnel via the cross conveyor. The rejection system includes an upgrade to a 12-inch touch screen.

Automated Buffer Refeed System

All dish filling lines include a fixed buffer table to provide temporary storage for stacks of dishes. The automated refeed system will feed these stacks of dishes back into the line so that they may pass through the outfeed and to downstream processing without manual intervention.

Temperature and Humidity Monitoring

An all-in-one sensor provides feedback of the temperature and humidity in the tunnel which can be displayed on the HMI or when paired with an MIS table (SCADA) can be a data collection point for a plantwide data system. This monitoring system can also trigger an alarm (stop the system) when outside of deadband parameters. (Parameters are specified during the design process and are adjustable via the HMI after installation.)

Full Cover Removal

Allows for full cover off drying of all standard plates. This function is standard on systems with contact plate production capabilities while standard function for non-contact plate allows for cover removal ranging from lids on to partial removal up to ~75%, adjustable from the HMI.

HEPA Monitoring and Control

Using a velocity sensor in the tunnel, the speed of the HEPA system is controlled by the PLC rather than the controls on the HEPA system itself. The PLC maintains the tunnel velocity based on a setpoint determined by the customer. This monitoring system can be used to set an alarm (stop the system) when outside of given deadband parameters. The velocity sensor can be used as a display on the HMI and when paired with an MIS table (SCADA) can be a data collection point for a plantwide data system. Velocity setpoint and deadband parameters are adjustable via the HMI. (This option is available only on systems with a tunnel length of least 10m.)

Belt Tracking System

Provides constant and automatic tracking of the main conveyor belt with the current status of the tracking system displayed on the HMI.

Blood/Additive Mounting

Provides a fixed location for the blood/additive pump assembly. The post style positions the assembly on a post mounted to the side of the machine, while also providing a hanging location for blood/additive bags. The slider style provides an adjustable position for the assembly on a track mounted over the input hood section.

Blood Bag Agitator

A blood bag agitator can be added to the line to ensure that blood remains in motion for the entire length of the production run.

Peripheral System Integration

When used with a MultiPREP™ media preparator, information can be shared between the devices.

HMI Upgrade

Increase the size of the touch panel. Standard operator panels include a 7-inch touch screen which may be upgraded up to 12-inch touch screen.

IQ/OQ Documentation

The Qualifications Package is a set of documentation provided at various stages of the production process. These documents are developed in collaboration with the customer and are intended to ensure that both parties agree with the design specification, the operational parameters, and the overall quality and performance of the system being delivered. These reports are considered separately from our internal qualification process.

Emergency Spare Parts Packages and Maintenance Kits

Maintaining the proper inventory of emergency spare parts and maintenance supplies helps to minimize costly downtime. Adding a spare parts package or maintenance kit to your new system order helps to protect your investment from day of delivery.

Service Contracts

Service contracts for training or periodic maintenance visits are available upon request.

Translation services available for all documentation and system interface components.

Many options are also available for retrofit upgrades to existing equipment

REQUEST PRODUCT INFORMATION